Introduction

Have you identified recurring issues in your traceability strategy? Low supplier engagement, a rigid platform, operational overload, unreliable data… These warning signs are hard to ignore — chances are, your current solution is reaching its limits.

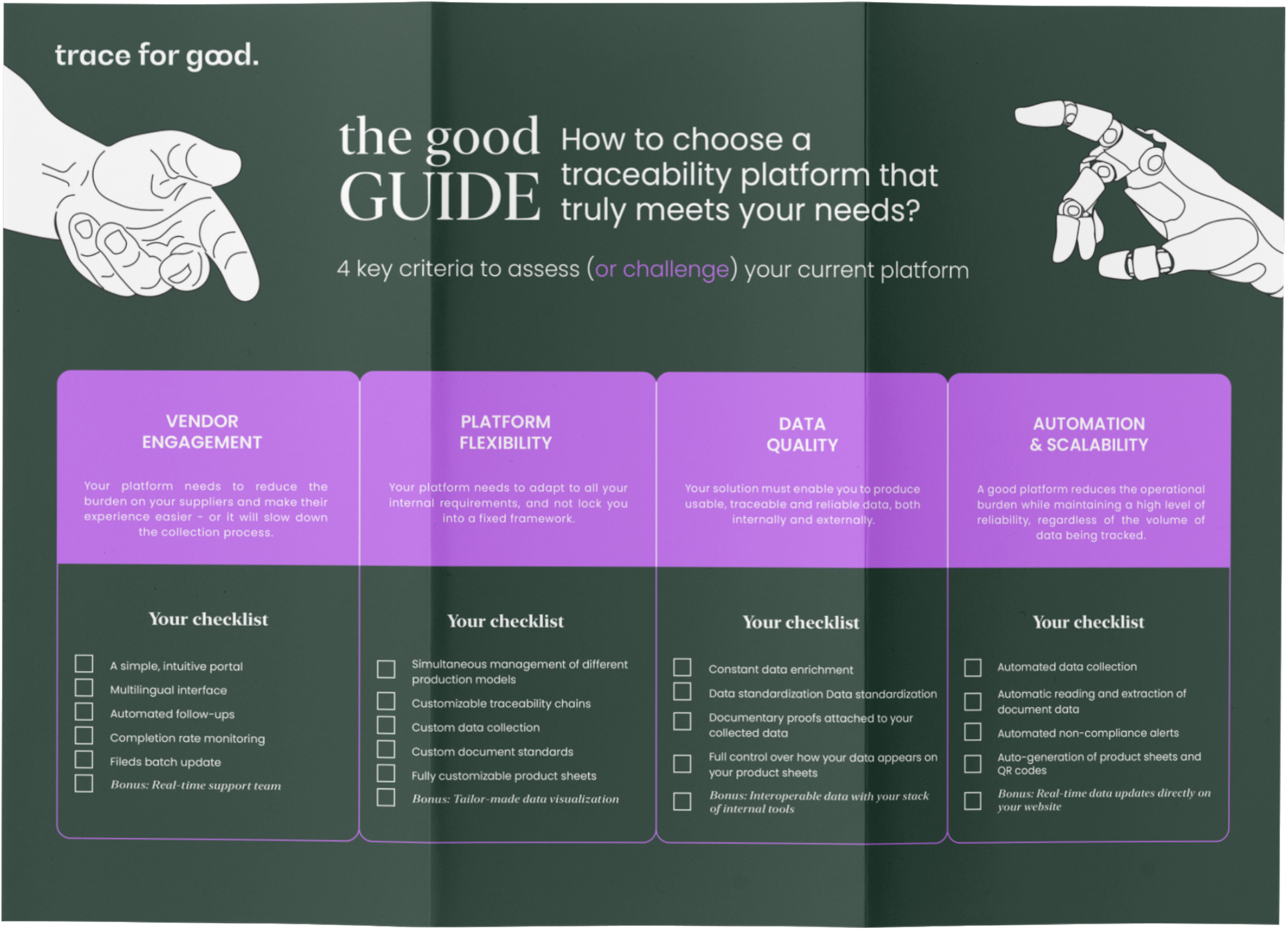

Before thinking about switching platforms, you first need to understand what separates a good tool from a poor one.

That’s exactly what this guide is here for: to help you gain clarity, define the right criteria, and choose a platform that’s truly built to go the distance — even at scale.

An effective traceability solution should act as a driver of agility, not an added constraint. It needs to adapt to your unique requirements, simplify collaboration with your suppliers, ensure the quality of collected data, and handle growing demands without friction.

So what are the key criteria that really make a difference?

Ready to dig in? Let’s break down the essentials to help you make the right call.

1. Your platform should reduce supplier fatigue

A traceability process only works if your suppliers actively participate. They’re the ones who hold and share the essential information about raw materials, production sites, and certifications.

Naturally, if your traceability platform is too complex, time-consuming, or unintuitive, supplier engagement drops — and with it, the quality and completeness of your data.

A high-performing platform should:

Provide a dedicated supplier space directly linked to your platform

Instead of juggling endless emails and spreadsheets, your suppliers should have access to a single, centralized portal for all your traceability requests. This space should allow them to manage and share their data easily — including with their own subcontractors — while protecting the confidentiality of their contacts when needed.

Reduce your suppliers’ workload

Suppliers often work with multiple brands and receive redundant requests. A good platform should auto-fill previously submitted information (for a product or collection) to avoid duplicate entries. It should also group similar requests, so if a supplier is asked for the same data across multiple products or orders, they only need to submit it once.

Automate supplier follow-ups and track engagement

Waiting without visibility can slow down your entire traceability process. A reliable platform should:

- Automatically follow up with suppliers so your teams don’t have to do it manually.

- Notify your team when a key supplier hasn’t responded or is falling behind.

These automations help you collect data more quickly and smoothly — and free up valuable time for your internal teams.

Be easy for your suppliers to use

Supplier engagement hinges on how user-friendly your platform is. A good solution should be:

- Clear and intuitive, with smooth navigation

- Available in multiple languages, to avoid language barriers

- Easy to use, with minimal need for training

2. Your platform must be flexible

For a traceability platform to be truly effective, it needs to adapt to the specificities of each business — not the other way around. As we discussed previously, a rigid solution that imposes standardized formats or overly strict constraints will quickly become a barrier to your organization and your traceability efforts.

It’s the platform that must adapt to your operations — not the other way around.

To truly align with your brand’s needs, an effective traceability platform should:

Take your different supply chains into account

No two brands operate the same way. Some manage seasonal collections, others handle regular restocks, and some do both. A good platform must support these varying models without forcing you to re-request information that’s already been collected for recurring references.

Adapt to your manufacturing model

The diversity of manufacturing processes (finished product vs. Cut Make Trim) calls for a traceability system that can follow those specific workflows without introducing unnecessary rigidity. Some brands may even use both models simultaneously across different product lines. Your platform needs to accommodate these realities without slowing you down.

Enable tailored data collection

Traceability needs often go far beyond regulatory compliance. You might have developed your own internal risk assessment model, track specific ESG indicators, or collect environmental impact data. A good platform should allow you to capture all the data points that matter to you, without forcing you into a rigid or predefined structure.

Handle multiple traceability chains with ease

You may have different traceability requirements depending on your product categories:

- 100% textile products

- Products combining textile and accessories

- Products containing leather or other specific materials

The platform must support these variations without adding unnecessary complexity.

Adapt document verification to your internal standards

Collecting data is only part of the story — compliance depends on the supporting documents you require. Some brands go beyond market standards, asking their suppliers for specific documents or certifications aligned with their internal commitments.

Your platform must allow you to define your own compliance rules (e.g., requiring a scope certificate for a particular material, or a social audit based on country of origin), and automatically verify that the submitted documents meet those expectations — not just general standards pre-built into the tool.

Offer flexible management of consumer-facing product pages

Traceability doesn’t stop at data collection — it must also be transparent and accessible. Your platform should let you generate consumer product pages tailored to your needs:

- You choose who manages them — either directly within the platform or internally via your teams.

- You control the design, thanks to brand asset integration for visual consistency.

- You decide what to show, whether it's regulatory data (legal requirements) or additional information (ESG criteria, environmental scores, material origin details, etc.).

Flexibility is therefore a key success factor: it enables efficient traceability without excessive constraints, reduces supplier fatigue, and improves data quality.

But flexibility alone is not enough. Your platform must also consistently ensure data reliability — regardless of scale or maturity.

3. Your platform must ensure the quality of the data you collect

As the volume of data you collect increases, the risk of degradation in quality grows too. The key to effective traceability lies not just in collecting large amounts of information, but in ensuring that information is accurate, verifiable, and actionable.

A robust platform should:

Continuously improve data accuracy

A good platform doesn’t freeze information at a single point in time. It should allow you to refine and enrich data as you go, integrating new inputs from your suppliers.

For instance, you might initially only have the recycled content percentage for the main component of a product. As your supplier shares more data about the other components, the platform should be able to automatically recalculate the overall recycled content, bringing it closer to reality — which is critical for requirements like France’s AGEC law.

The result? More precise, more reliable data — without creating extra work for your teams.

Allow suppliers to upload supporting evidence

A self-declared data point is only as strong as the documentation behind it. Your platform should enable suppliers to attach evidence (certificates, audits, invoices, attestations, etc.) directly to the information they provide. This not only strengthens reliability but also helps reduce the risk of errors or manipulation.

Standardize your data to make it usable

Effective traceability often involves exchanging information with other systems (like ERP, PLM, or compliance software). Your platform must support data standardization, ensuring interoperability without compromising quality or introducing inconsistencies during transfer.

Give you control over what’s displayed to consumers

Not all data collected is ready to be published as-is. Your platform should give you full control over which information is made public, especially when anomalies or questionable data points arise. That way, you can avoid sharing inaccurate or misleading content — protecting your brand’s transparency and credibility.

An effective platform doesn’t just ensure reliable data — it also gives you control over how it’s used and shared.

But as the volume of data increases, the manual effort required to qualify and verify it becomes a real bottleneck. That’s where automation comes in.

4. Your platform must automate low-value tasks

As the number of orders, suppliers, and product references grows, collecting and verifying traceability data becomes increasingly complex. Without automation, your team’s workload quickly balloons — slowing down processes and putting data quality at risk.

A truly effective platform shouldn’t just centralize information: it should automate as many tasks as possible to ensure smooth, scalable traceability management.

A solution that’s truly scalable should offer:

Automated data collection

Once your traceability process is in place, your platform should be able to take over automatically — sending requests to the right suppliers at the right time, with no manual intervention.

The result: your teams no longer waste time chasing responses, and your data is collected faster, more proactively, and without friction on the supplier’s end.

Automatic document reading and data extraction

Managing certificates and compliance documents shouldn’t be a time sink. Your platform should integrate AI technologies to extract key information from your scope certificates, transaction certificates, social audits, and more. This allows you to:

- Automatically link certificates to the right products

- Reduce the manual burden of sorting and verifying documents

- Gain speed and accuracy in document processing

Automated non-compliance alerts

Discovering a problem after a product hits the market can be costly — think product recalls, reputational damage, or regulatory penalties. Your platform should automatically flag non-conformities upstream, with alerts tailored to your specific requirements. This way, any anomaly in a certificate, attestation, or supplier-provided data can be caught before the traced product is commercialized.

Automated QR code and traceability page generation

A high-performing platform should also automatically generate product QR codes and dynamic traceability pages that consolidate and display the most up-to-date information.

A solution that automates these steps can handle growth without overloading your team. It improves data quality, reduces human error, and frees up time for higher-value work.

Conclusion: A good platform must tick these 4 boxes

Supplier engagement, flexibility, data quality, automation… Effective traceability relies on balancing these four pillars.

Too often, brands choose tools that perform well on one front — but fall short on the others. And yet, it’s the combination of these capabilities that really makes the difference.

No supplier engagement without a smooth user experience. No reliable data without proper document verification. No scalability without automation. And no efficient traceability without a solution that fits your internal processes.

Choosing the right platform means choosing a solid foundation for your traceability strategy — one that can support your goals today, and evolve with you tomorrow. And while supplier engagement is often the most visible piece, it won’t work without the right technical and functional backbone.

Want to go deeper into this topic?

Download our Supplier Engagement Playbook for concrete advice and best practices to help build a long-lasting, collaborative approach.

.jpg)

.png)

.png)

.jpeg)